Emerging of Jewelry Grade Synthetic Diamond

Home Page

Potential Market

Industrial Diamond

Previous Attempt

Synthetic Jewelry

Guest Book Page

Who we are

Contact us

Technology Know-How

Problem that old Technoloyg cannot make Jewelry Grade Synthetic Diamond

In 70's, GE has developed a new technology that can create Gem Grade Diamond. However, high production cost make it can never be commercialized. In addition, the method of crystallization under the machine is totally different from that creating nature diamonds. Impurities such as cobalt, iron and nitrogen make the diamond manufactured yellowish and magnet like. It also creates defects in the crystal that the diamond can be broken easily. These disadvantages further limit the use of the technology in production of jewelry used diamond.

There are many later attempt has been done. However, the cost, the technology, the method and also the business benefit has further limited the progression. More important, the scientist in these organization will lost the job if they has complete the research, and the patent will be belonged to the Company. Therefore, nobody will do it before they will be fired no matter they success or not. Even the empolyer is a good man, the scientist can got less than 5% of the benefit. In university, this research has no academic value and therefore no fund will be put to do it.

There are many later attempt has been done. However, the cost, the technology, the method and also the business benefit has further limited the progression. More important, the scientist in these organization will lost the job if they has complete the research, and the patent will be belonged to the Company. Therefore, nobody will do it before they will be fired no matter they success or not. Even the empolyer is a good man, the scientist can got less than 5% of the benefit. In university, this research has no academic value and therefore no fund will be put to do it.

Impurities inside the Synthetic Diamond

The main difficulty to create Jewelry Grade Synthetic Diamond is the impurities. Impurities enter the crystal during crystallization in the chamber and being part of the crystal. For example, the iron or cobalt used as a catalyst (more accuracy, as a solvent) may enter the crystal to make the crystal react like a piece of iron under a magnet.

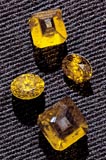

Nitrogen Further Make it Yellow in Color

The impurities also make the diamond ugly too. Although some impurities such as Boron can make the color of diamond blue ??which is the most expensive nature diamond, the harmful impurities such as nitrogen can much it ugly yellowish. It makes the diamond in an ugly uncompensated situation.

Many experiments are also done to further increase the size of the diamond. However, most of them are done to make larger crystal for industrial purpose. For example, Japanese company such as Sumitomo Inc. has already produced a diamond crystal plate of about 50mm in diameter. Such crystal is ugly yellowish and magnetic reactive. This crystal is used to prepare heat sunk for expensive electronic device only. In addition, DeBeers has also made some diamond with ugly marks on the surface too.

Attempt to make Super Size Synthetic Diamond

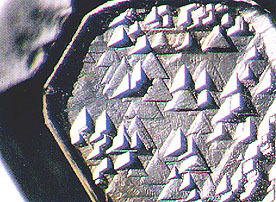

Impurities inside the Diamond (12X)

Nitrogen make diamond yellowish

Large Synthetic Diamond made by DeBeers consist of Tranglar Marks